- Fleet testing of Geely methanol cars with unique fuel from CO2 show highly positive results

- Vehicles subject to an eighteen rigorous month test in the unique Icelandic environment

28 November 2017, Kopavogur, Iceland. For the last 18 months, a fleet of six methanol powered Geely Emgrand cars have been undergoing rigorous real world testing in Iceland. Geely Auto’s Emgrand M100, the world’s first mass produced methanol vehicles have been operated by Carbon Recycling International (CRI) on Icelandic roads.

Iceland-based Carbon Recycling International, which is invested in by Geely Holding Group, is the world leader in power to methanol technology. They produce renewable methanol using recycled carbon dioxide emissions derived from a local thermal power plant and hydrogen made by splitting water with electrolysis.

The methanol fleet test is a collaboration between Geely, CRI and Brimborg, a local dealership and automotive service provider.

In the recently concluded first phase of the fleet test, the cars were driven over 150,000 kilometers over an 18 month period. Among drivers testing the vehicles were CRI staff and members of the Icelandic Automobile Association as well as several local automotive service providers. The participants reported virtually no difference in driving experience compared to regular gasoline or diesel fueled cars.

Similar appearance and driver experience

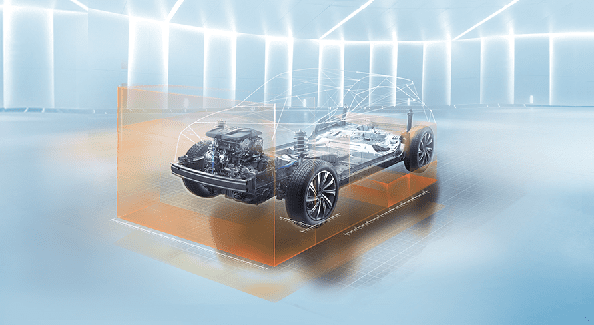

The Emgrand M100 is a methanol variant of the best-selling domestic sedan in China, the Emgrand 7 with average sales of over 20,000 units per month. Geely Auto has been a long term pioneer of methanol vehicles in the Chinese market and has worked closely with Carbon Recycling International to make the road test a reality.

The methanol variant of the Emgrand 7 features a 1.8L engine which can run on both methanol and gasoline. The version used in the fleet test has a 50 liter methanol tank as well as a 10 liter gasoline tank. The methanol powered car starts with fuel from the gasoline tank and automatically switches to methanol once a preset temperature has been reached in the engine. The switch from gasoline to methanol is completely seamless. A two-tank design was used to avoid any problems during cold starts because methanol is stable at a low temperature and therefore evaporates slowly in the Icelandic climate, unlike gasoline.

Methanol in high demand as a fuel in China

Geely developed the methanol version of the Emgrand for the Chinese market, where use of methanol is an automobile fuel has increased rapidly over the last few years. Several Chinese provinces, including the major metropolis of Shanghai have adopted standards for methanol and gasoline blends. The most common blend contains 15% methanol and 85% gasoline.

Currently, China produces most of its methanol from coal. CRI now works closely with Chinese partners to introduce more environmentally friendly production facilities, using CRI’s proprietary CO2-to-methanol technology.

Significant reduction of CO2 emissions and other tailpipe emissions

According to CRI’s Director of Sales and Marketing, Ómar Sigurbjörnsson, who managed the fleet test, using methanol fuel allowed for a 70% saving in CO2 emissions in a well to wheel comparison that includes all upstream, manufacturing, distribution and tailpipe emissions. The average in use emissions were calculated at 46g of CO2 per kilometer when accounting for both fuels in use within the methanol vehicles.

Sigurbjörnsson commented on the conclusion of the test: “We have found that methanol fuels when compared to diesel or gasoline burn at a much cleaner rate, offering cleaner combustion that is free of soot and emits no traces of sulfur or cancerous materials that are found in other fuels. With the conclusion of this test, we believe that methanol fuels will be economically competitive with both fossil fueled cars, hybrid vehicles and electric cars.”

These positive results encourage CRI and its partners to engage in further development of renewable methanol use in vehicles. Planning for the next phase is already underway.

Further advances in reducing CO2 emissions in transportation are necessary to meet international commitments to counter climate change. Current International efforts have been focused on commercialization of electric and hydrogen vehicles but an alternative approach using renewable methanol as an energy carrier could address some of the technical and economic challenges. Renewable methanol, a liquid and energy dense fuel is also a more competitive solution for heavy goods road transport and marine transport, enabling the indirect electrification of vehicles used in those sectors.

Liquid fuel produced with electricity does not require drastic changes in infrastructure

Methanol has been used as a racing fuel for many decades. Unlike methane gas and hydrogen, there is no need to install expensive infrastructure in order to store and distribute methanol as a fuel. Furthermore, cars such as the Geely Emgrand Methanol Variant can be manufactured in the same facilities as other fossil fuel vehicles, using the same platforms as gasoline or diesel powered vehicles which drastically reduces production costs compared to electric or hybrid vehicles.

According to Mr. Sigurbjörnsson, “methanol can also be used to generate electricity onboard using fuel cells. Methanol that is produced with CRI’s method is one of the most environmentally friendly liquid fuels available today. Methanol fuel enables car manufacturers to design lighter, powerful engines with more efficiency than can be achieved in the design of traditional gasoline or diesel engines. CRI are also participating in projects where renewable methanol is already used to extend the range of battery electric cars and ferries,” says Sigurbjörnsson.

About Carbon Recycling International

Carbon Recycling International (CRI) is the world leader in power to methanol technology. They produce renewable methanol from carbon dioxide, hydrogen, and electricity for energy storage, fuel applications, and efficiency enhancement. They are a technology provider to the power generation and industrial production industries. Their solutions are environmentally friendly and do not impact the food chain or land use.

Website: www.cri.is