2018 July 26, Hangzhou Bay, Ningbo. After developing the CMA – Compact Modular Architecture together with Volvo, Geely Auto has unveiled BMA, a new modular architecture for B-Segment compact cars. The new B-segment modular architecture maintains the high flexibility and scalability inherent in Geely Auto Group’s CMA.

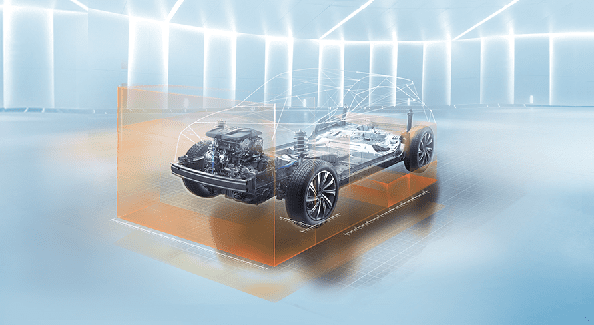

The development of Geely’s BMA is the result of a four year effort by nearly 100 modular architecture experts from over 20 countries based in Geely’s research and development center in Hangzhou Bay. The BMA architecture can be visualized as a collection of power, electrical, chassis, and body modules which can be freely combined like building blocks to create an endless variety of vehicles. The interface between each module is standardized allowing developers who follow the architecture guidelines to create any vehicle shape they see fit; from sedans to crossovers to MPV’s to SUV’s. New vehicle development time have been shortened to 18-24 months. One of the rationale behind the development of BMA was to meet the needs of young users who demand more spacious, enjoyable, and personalized vehicles.

BMA Charecteristics

1) Flexibility and Scalable – The highly flexible BMA can be used for the development of multiple sizes and types of vehicles from A0 to A+ and from SUVs, Sedans, Crossovers, Wagons, to MPVs. The architecture can be used to develop cars with a wheelbase as short as 2550mm or as long as 2700mm and with distance between wheels ranging from 1500-1600mm. Length and width can be adjusted as desired by the design and engineering team. As a modular architecture, it comes with inherent scalability allowing production to be optimized for speed

2) Multiple Powertrain Options – Developed with future electrification in mind, the BMA supports a variety of power options. Models using the BMA architecture can be equipped with Geely’s 1.0TD, 1.4T, 1.5TD, along with hybrid powertrain systems such as PHEV, HEV, or MHEV.

3) Advanced Active and Passive Safety – BMA was developed with passenger and pedestrian safety as its highest priority and is developed from 70% high-strength steel and 20% hot-formed steel. It was designed to exceed Europe’s 5-star safety standard with leading active safety features as well as the capability to immediately handle L2 autonomous drive and L3 autonomous drive in the future.

4) Increased Interior Space – The BMA has the unique advantage of being optimized for interior space, achieving class leading space utilization. Space does not need to be sacrificed in a BMA compact car. Powertrain, suspension, seat position, ergonomics, and component layout has been optimized to ensure maximum interior space.

The use of BMA allows for strong economies of scale as all BMA based vehicles will have a high rate of commonality with shared parts and components reaching 70%, reducing time needed for component testing and lowering costs. The higher scale also encourages suppliers to improve the performance and quality of their parts. At the same time vehicle development time will be cut from over 36 months on average to just 18 to 24 months, allowing Geely to stay at the forefront of the market by quickly responding to user demands and provided users with vehicles they require.

BMA was developed to support the latest advancements in vehicle safety, connectivity, power, and intelligence. The BMA will provide users with more space, better power, better safety, and faster connectivity. As well as benefiting users, BMA’s scalability, cost reduction, and ability to comprehensively meet user demands will become an important pillar of support for Geely in meeting their “20200 strategy” goal of achieving 2 million in annual sales by 2020.